Choosing a Remanufactured Dodge Transfer Case for Performance and Value

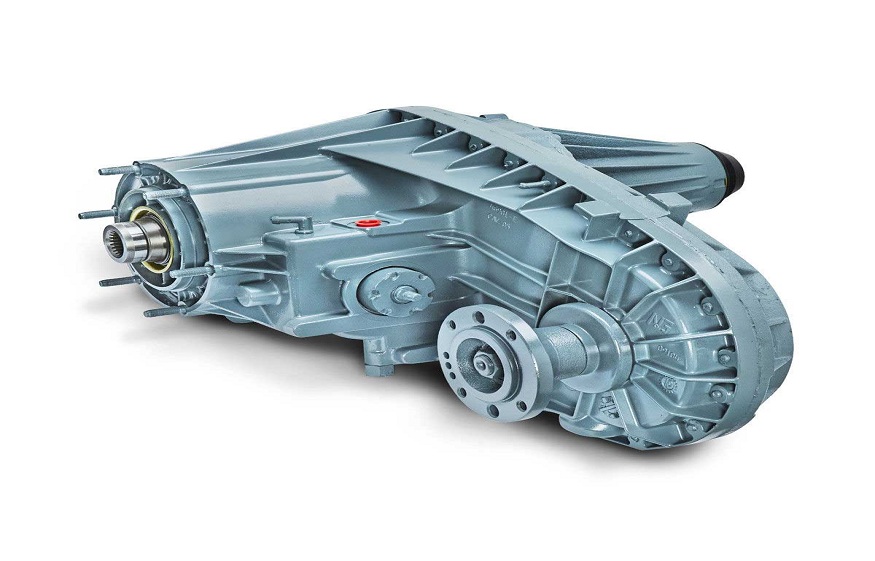

When a Dodge vehicle begins to show signs of drivetrain issues—particularly problems with shifting, grinding noises, or a loss of four-wheel drive functionality—the transfer case is often the source. It plays a critical role in directing power from the transmission to the front and rear axles, enabling proper torque distribution. For Dodge owners experiencing transfer case failure, opting for a remanufactured Dodge transfer case presents a practical and cost-effective solution that balances durability, value, and OEM-grade performance.

Modern Dodge trucks, SUVs, and full-size vehicles are built to handle heavy loads, varied terrain, and changing driving conditions. Their drivetrain systems are designed with toughness in mind. However, like any mechanical component, transfer cases are subject to wear over time. Internal chain slack, gear wear, and seal breakdown can cause a gradual loss in performance or even complete failure. Once symptoms appear, drivers must act quickly to avoid damage to other drivetrain components.

A remanufactured Dodge transfer case offers a reliable option that restores functionality while maintaining the structural integrity of the original part. Unlike used parts, which are pulled from vehicles with no guarantee of longevity, remanufactured units are rebuilt with care and precision by skilled technicians. Every component is cleaned, inspected, and replaced as needed, ensuring the unit functions as it should.

What Sets a Remanufactured Dodge Transfer Case Apart

The process of remanufacturing involves far more than superficial repairs or cosmetic upgrades. Each transfer case is completely disassembled. Technicians clean the housing thoroughly, inspect gears and bearings, and replace all worn or damaged components with new or re-machined parts. The unit is then reassembled and tested under rigorous standards.

One of the advantages of choosing a remanufactured Dodge transfer case is the ability to benefit from design improvements that may not have been present in the original. Manufacturers and rebuilders often identify known failure points and resolve them during the remanufacturing process. For Dodge vehicles that are exposed to rough terrain, towing, or heavy-duty driving, these enhancements can make a noticeable difference in performance and longevity.

The final step before shipment is thorough testing. Most remanufactured cases are subjected to pressure testing, torque verification, and fluid seal validation. These steps ensure that the unit operates correctly and will integrate seamlessly with the vehicle’s existing systems. This level of attention to detail means that many remanufactured units perform equal to—or better than—the factory originals they replace.

Another benefit is availability. New Dodge parts can be expensive or difficult to locate, especially for older models. Choosing a remanufactured part ensures faster turnaround and often includes limited warranties, providing reassurance without inflating repair costs.

Financial and Practical Benefits for Dodge Owners

For many Dodge owners, replacing a failed transfer case with a new OEM part is not financially practical. The cost of a brand-new unit from the dealer can be substantial, and if the vehicle is outside warranty or several years old, the expense may not align with the car’s current value. A remanufactured Dodge transfer case offers a financially sound alternative without sacrificing performance.

The cost savings can be significant, especially when labor is also factored in. Most remanufactured units are sold as direct-fit replacements, meaning no modifications are needed during installation. This reduces shop time, lowers the chance of installation errors, and minimizes the downtime the vehicle experiences. For those who rely on their Dodge for daily commuting, work, or towing, these savings in both money and time are invaluable.

Even for performance-focused owners or those maintaining older Dodge models for hobby purposes, the remanufactured option provides accessibility to parts that might otherwise be discontinued. Rather than hunting through salvage yards or relying on questionable online sellers, customers can purchase a rebuilt unit that is ready for immediate use and supported by a professional remanufacturer.

Fleet owners and commercial operators also find value in using remanufactured transfer cases for their Dodge vehicles. When managing multiple vehicles, controlling costs is essential, and choosing rebuilt parts helps maintain reliability across the fleet without exceeding budget constraints. Repeatable quality and shorter lead times make this approach a logical choice for long-term maintenance planning.

Supporting Performance and Environmental Responsibility

Many drivers may not consider the environmental impact of auto part replacements, but the decision to install a remanufactured Dodge transfer case supports sustainability efforts. Instead of discarding the existing unit and manufacturing an entirely new one from raw materials, the remanufacturing process reuses the original housing and other key components, significantly reducing material waste and energy consumption.

This approach minimizes the demand for newly mined metals and petroleum-based materials, helping reduce the overall carbon footprint of automotive repairs. With growing awareness around eco-conscious consumer behavior, more vehicle owners and shops are turning to sustainable solutions that don’t compromise performance.

When rebuilt correctly, a remanufactured Dodge transfer case delivers the same rugged capabilities that the brand is known for. It maintains strength under pressure, responds well to various terrain demands, and ensures that the driver can rely on proper torque distribution for both routine and heavy-duty driving. Whether navigating snowy roads, muddy construction sites, or long stretches of highway, the restored unit supports full drivetrain function and consistent traction.

Installation and Compatibility Across Dodge Models

Remanufactured Dodge transfer cases are available for a wide variety of models, including Ram trucks, Durango SUVs, Dakota pickups, and older platforms such as the Ramcharger. Each unit is rebuilt to match the factory specifications of its corresponding model, including gear ratio, electronic compatibility, and mounting configuration. This makes installation more predictable and reduces the likelihood of misfits or mechanical complications.

Working with a reputable supplier ensures the right match for a vehicle’s year, engine type, and transmission. Experienced suppliers maintain detailed records and databases to verify compatibility before the unit is shipped. In many cases, the unit will arrive pre-tested, pre-lubricated, and fitted with essential sensors or switches required for immediate installation.

For mechanics and repair shops, this convenience helps maintain efficiency and customer satisfaction. When the part arrives ready to go, technicians can focus on accurate installation and testing rather than improvising or adapting components. This is particularly important for transfer case replacements, which require precise alignment and connection to the driveshafts and other drivetrain components.

For the everyday driver, this translates into getting the vehicle back on the road faster and with less hassle. Confidence in the part’s performance and compatibility helps ensure smooth operation once the job is complete.